Growing Demand for Hot Beverages and Food Propelling the Market Growth of Paper Cups

According to the United Nation’s reports, over 80 countries around the world now have a full or partial ban on single-use plastic. And the list is growing every year. The global paper cups market size was valued at $5.5 billion in 2020 and expected to reach $9.2 billion by 2030, with consumption growing at a CAGR of 1.4% in the forecast period of 2022-2027.

The global market for paper cups has been driven by the growing demand for hot beverages, including tea and coffee, in recent years. Further, the paper cups also find applications as a container for chilled food and beverages, thereby adding to the overall market growth. The market has been witnessing healthy growth in developing countries of the Asia Pacific region, where the expansion of food delivery services has observed robust growth in the recent years. This can be attributed to the hectic lifestyles and busy schedules of customers. Further, the usage of paper cups is increasing due to their convenience as it saves time and effort and can be discarded easily after their usage. With the consumer becoming increasingly environmentally conscious, they are choosing these paper cups over disposable containers made of plastic. Additionally, the rising awareness regarding cleanliness and hygiene has shifted the consumer preference from reusable cups to disposable cups, thereby catalysing the market expansion of paper cups. Government policies incentivising the recycling of papers cups are giving the global market for paper cups a further boost.

Paper cup manufacturing business could be profitable-as the net profit margin of paper cup manufacturing business is around 15%-20% in middle east countries-but the market could be fiercely competitive in some countries, such as Iraq and Egypt. If you are considering going into this market , here are a few steps and detailed tips on how to start paper cup manufacturing business from scratch. Hopefully they could be really helpful for you.

Market research

It is advisable to do local market research before starting paper cup manufacturing business, figure out what your target customers value the most-is it the better quality or just the lowest price, etc. It will determine how many and what kind of machines you gonna purchase, which will play a significant role in determining the amount of your upfront costs. Please refer to below 4 steps:

- Figure out “4P”(Product-Price-Place-Promotion).

- Listing your major competitors and finding out how your competitors are doing successfully.

- Find out sales target group.

- Make a marketing plan and forecast your sales

How To Choose a Cup Forming Machine

There are many different suppliers of paper cup machine on the market. How can we choose a cup forming machine that most suits us ?

- Firstly, choose the high price machine or low price one? The prices of Paper cup forming machine in China are ranging from as low as 9,300USD to as high as 40,000USD, how do we choose the one that suits us the most? First of all, we should figure out what kind of market we will enter and what kind of paper cups we will be manufacturing. Market and cups determine what kind of machine you should buy. For example, if you are going to manufacture special customized cups or consider enter into high end market, you should buy high quality cup forming machine, which is more expensive. but high-end market means high profit margin, we will earn the upfront costs back quicker. As high-quality paper cup forming machine have these advantages - stable running, lower waste rate, longer service life. Leading manufacturers like SINI Machinery China (price 23,000USD-38,000USD) and NewTop Machinery China (price 30,000USD-40,000USD) famous for the said features. 23,000USD-40,000USD may sound a little expensive for many people. SINI machinery could usually run smoothly for 10 years without overhaul. Some lower price machines around USD10,000 can run smoothly for 5 years without overhaul. Short service life means you may need to change new aluminum alloy mold due to its low wear resistance, and need to change transmission system faster than you think. If you are gonna manufacture cups with lower price and you are on a tight budget, you could choose cheaper machines. But I if you’re considering manufacturing high-end cups and you have the budget to invest, choose the better machine because it’s totally worth it in the long run.

- Secondly, better after-sales service and timely technical support should be considered. Leading manufacturers like SINI machinery and NewTop machinery is well known for their excellent after-sales service and technical support. What’s the difference between good after-sales service and poor service? Imagine this, you encounter machine failure and your production lines are shut down, you are losing money minute by minute. Just one call and the supply side will assign their best technical engineers to help you solve the proplem via video chat in no time! When the machine part is broken, the supply side will immediately send you a new machine part. Package arrived, installation completed And boom! Problem solved! Everybody back to work! How’s that sounds like? On the opposite, poor service machinery company may take up to 3 days to get back to you. And take couple more days to send out the related machine parts. Some even don’t get back to you at all. You just sit tight and wait in despair because there is absolutely nothing else you can do about it. You wouldn’t want that, would you?

- Thirdly, choose ultrasonic system or Heat system ? It is advisable to choose ultrasonic system cup forming machine, particularly for those who manufacture paper cups with wall thickness more than 300μm. Ultrasonic can easily penetrate the high thickness paper for good sealing and forming. Ultrasonic save your operating time and they are suitable for many different types of paper.

Working space and Power required

A paper cup manufacturing factory working space should be no less than 800 to 1000 square feet. The cup forming machine should be operation at 50Hz, voltage of 380v, 3-phase. The machine cannot work under household electricity of 220v.

Raw material associated to production:

- Paper cup fan (printed, die-cutting, without waste paper)

- Bottom paper

- Plastic bag (packaging material)

- Carton (packaging material)

- Silicone oil

- Watering cans (spray water on fan)

- Iron shelving (place paper cup fan)

- Hand pallet trucks or Electric trucks

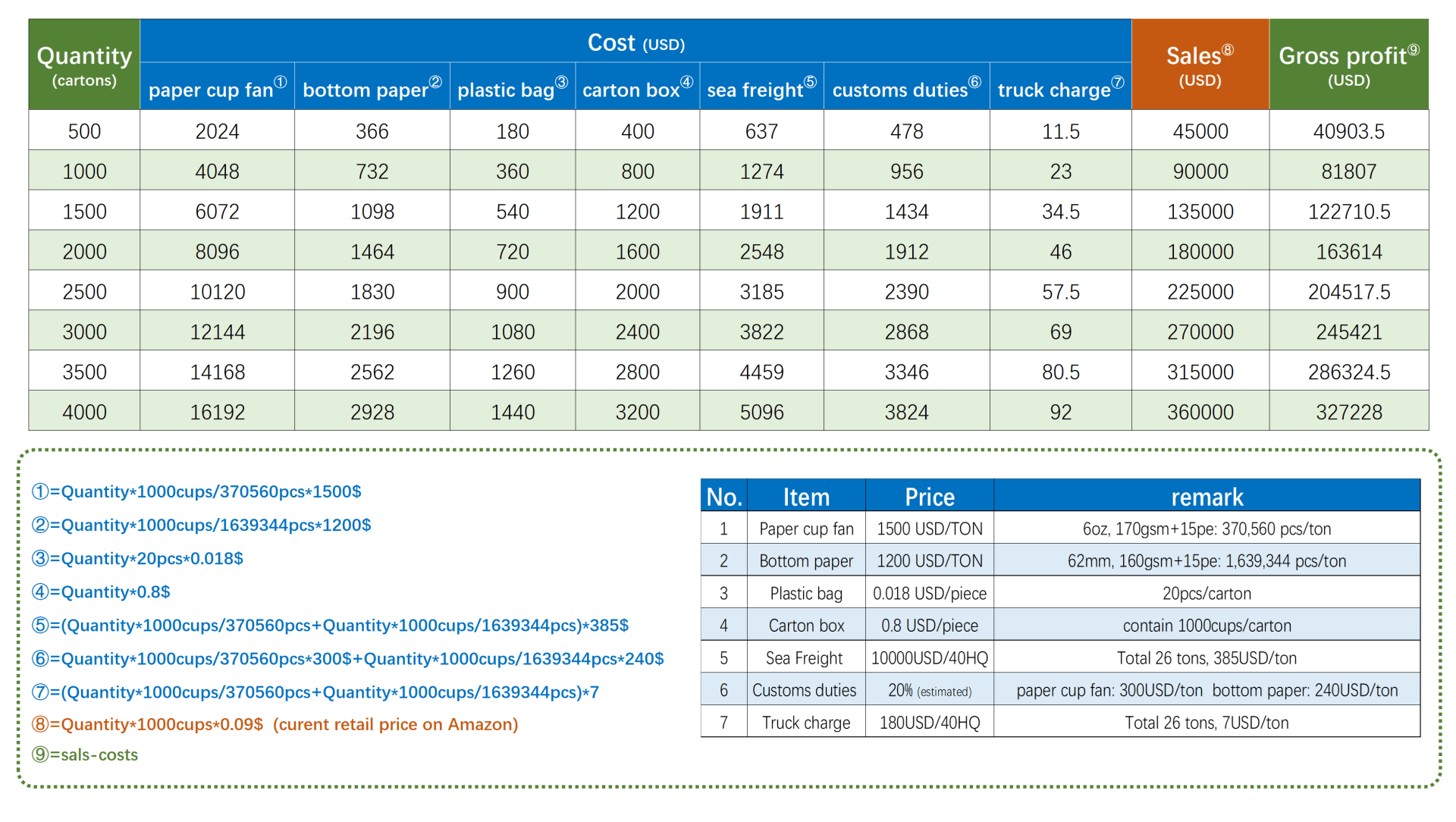

How to calculate gross profit ?

Example: Let's say you’re a paper cup manufacturer from UAE, you have 2 cup forming machines of 6oz with speed 80pcs/minute. Port of loading is Shenzhen port, China. Destination is Dubai port, UAE. How to calculate your gross profit?

A 6oz paper cup is made from a bottom paper(160gsm+15pe)and a paper cup fan (170gsm+15pe, printed 1-4 colors, die-cutting)

So there you have your gross profit! Don’t forget to take out rents, utilities, employee wages for net profit.

Conclusion

Running a paper cup manufacturing business definitely could be a profitable investment. And the global demand for paper cups is increasing rapidly as more and more countries banned the use of plastic. Hopefully my tips could really help you start a paper cup factory. Good luck!

Leave me a comment with any questions or email me at chris@guimapaper.com

Get In Touch

Tel: +86-771-4923380

Phone: +8618378845537

Email: chris@guimapaper.com

- Mon - Fri

- -

- Sat - Sun

- Appointment Only